About Gokul Dairy –

As a part of immersion visit to Sangali, Kolhapur and Goa, we got the opportunity to visit Gokul Dairy situated at Shirgaon, Kolhapur. The Dairy was established on 16th March 1963. Gokul stated with the capacity of 700 litre per day but at present Gokul has modern 7 lakh liters per day capacity dairy plant. Their products include Milk, Shrikhand, Ghee, Table Butter, Skimmed Milk Powder & Desi Butter.

After reaching Gokul Dairy, we met Mr. R C Shah who is currently General Manager of plant. He told us the brief history of Gokul, current production capacity, financials and future scalability plans of dairy.

Key points of discussions:

- Dairy procure 50 % buffalo milk and 50 % cow milk from 450 societies. After processing the milk 80 % liquid milk is sold and rest 20 % milk is used to produce Shrikhand, Ghee, Table Butter, Skimmed Milk Powder & Desi Butter.

- During processing, milk is heated at 78 °C for 15 seconds and then chilled at 4 °C.

- Current capacity of plant is – they can produce 42 tonnes butter per day, 40 tonnes milk powder per day and 6 tonnes ghee per day.

- Milk can be stored for 4-7 days in plant.

- 80 % water needs to remove to produce milk powder.

- During summer milk production is low so they use milk powder to fulfill the demand of milk. 10 litres of milk can be made from 1 Kg of milk powder.

- For packaging the milk, they use plastic pouch. Unused or discarded milk pouch is sent for recycling.

- All the dairy equipment is cleaned by chemicals and detergent to avoid the contamination in milk.

- Main problem is they need approximately 1.3 litre of water to process 1 litre of milk.

- There is loss of 2-3 % of fat and cream when they clean the dairy equipment.

- Farmers are paid on the basis of quantity of fat in milk which they give it to Gokul Societies.

- Generated scrap material in plant is sold kabadiwalas in Kolhapur.

Effluent Treatment Plant (ETP)

There is lot of water wastage in cleaning the dairy machinery and that waste water can’t be directly mixed in drains because BOD and COD is very high. So Gokul Dairy has its own Effluent Treatment Plant (ETP) and its capacity is 12 lakhs lit per day.

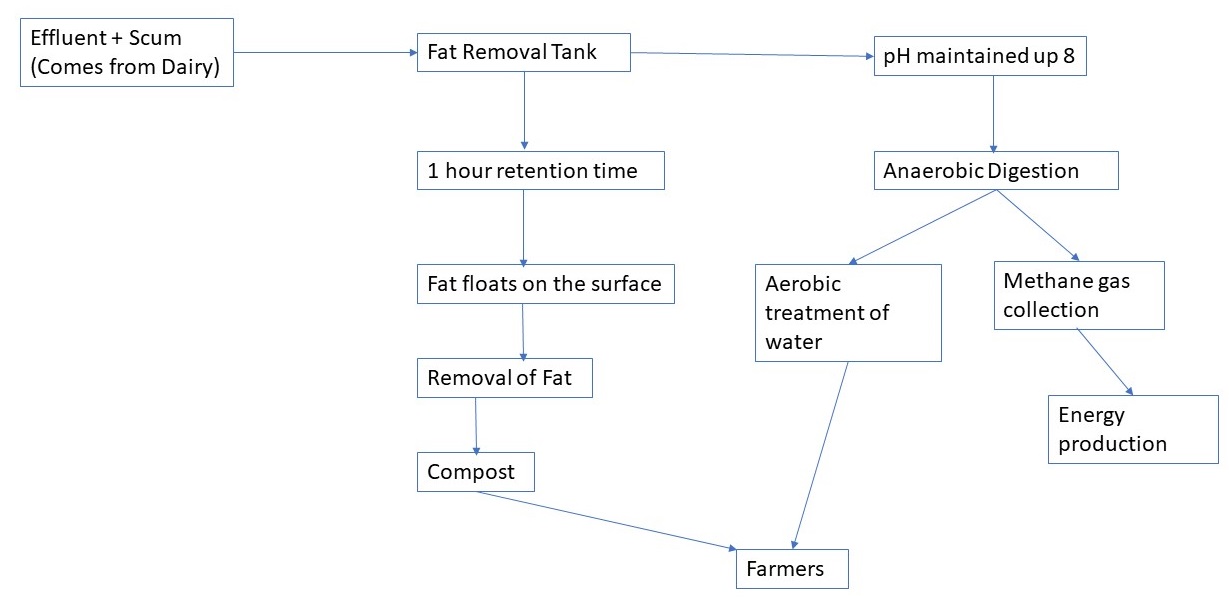

Below diagram shows the functioning of ETP : –

Removed fat is composed and then sold to farmers. On another hand water goes through anaerobic digestion where methane gas is collected and used for energy production and rest water goes for aerobic waste water treatment tank and then finally it is given to farmers for irrigation purpose.

Removed fat is composed and then sold to farmers. On another hand water goes through anaerobic digestion where methane gas is collected and used for energy production and rest water goes for aerobic waste water treatment tank and then finally it is given to farmers for irrigation purpose.

Author: Pramod Bhurji, BIRAC Social Innovation Immersion Programme Fellow at Venture Center, Pune.